Guideline for selecting an internal insulation system

Internal insulation systems are generally composed of several materials ensuring the necessary functions, such as insulation, structural stability and finishing.

Various internal insulation systems and products are available on the market. They mainly differ in terms of material properties, installation method, environmental impact, durability and costs. Based on the hygrothermal properties of the insulation material, the internal insulation systems can be subdivided into two main groups: vapour-tight and vapour-open systems.

A vapour-tight internal insulation system

prevents the warm, moist indoor air from penetrating the insulation. It can be obtained by using a vapour-tight insulation material or, alternatively, by coupling a vapour barrier to a vapour-open material. Particular caution is always required when a vapour barrier is adopted, as any disconnection or perforation of the barrier determines a possible vapour penetration, thus a significant decrease in the system performance.

A vapour-open internal insulation system

is generally obtained by using a vapour-open insulation material that also enables capillary suction (capillary-active insulation material). The capillary activity of the material, in fact, allows the moisture transport through the insulation material towards the indoor air if the inner surface of the existing wall gets wet, for instance due to interstitial condensation.

Insulation systems

With a barrier

Condensate-preventing systems disable vapour transfer from the room side into the construction by a vapour barrier.

Tight in itself

Condensate-limiting insulation systems include a vapour brake.

Open for diffusion

Condensate-tolerating insulation systems consist of capillary active insulation material and glue mortar.

The installation procedure usually includes the following phases:

Decide the type of insulation system, thickness and installation method

Remove everything fixed to the walls to be insulated (e.g. plug sockets, light switches, curtain rails, radiator, etc.)

Clean and prepare the wall surface (i.e. knocking off old plaster if damaged)

Install the insulation system according to the instructions of the manufacturer by directly fixing the thermal insulation to the wall or by creating a new internal stud

Eventual reinstallation of previously removed items

Install the insulation by directly fixing thermal insulation to the wall: In case of sufficiently rigid insulation boards, the insulation layer can be directly fixed to the wall by using a specific adhesive or mechanical fixing. The installation is then finished at the interior by using a specific rendering system or through gypsum plasterboards directly glued to the insulation material.

Install the insulation by creating a new internal stud: In case of a more flexible insulation material, a new stud wall is generally built, leaving a ventilated cavity between the existing and the new counter-wall, that is finished with gypsum plasterboard.

Since installing an internal insulation system requires removal and re-fixing of several items, such as switches, radiators, etc., it is important to consider the best insulation solution/material for each specific case, also taking into account the possible occurrence of moisture-related problems, such as frost damage, interstitial condensation, mould growth and other damage patterns that may occur when an internal insulation system is applied. In this case, it is advisable to ask the opinion of an expert or to perform a more in-depth study to evaluate the possible occurrence of moisture-related issues and, then, to select the insulation system suitable for the specific case.

Examples of insulation materials

Insulation materials that can be used for internal insulation in historic buildings can be classified according to various principles, for example, as coming from natural occurring materials or man-made materials, or as traditional, state-of-art and future thermal insulation materials.

Read more in the report State of the art on historic building insulation materials and retrofit strategies

Cellulose fibre (natural material) is the basic raw material for both wood fibre and wood wool insulation.

Cork fibre (natural material) is the basic raw material for both wood fibre and wood wool insulation.

Mineral wool consists of the basic raw materials sand and basalt rocks.

Polyurethane (PUR) is a material with closed pores obtained during chemical reactions.

Polyisocyanurate (PIR) is a polymeric insulation material with the same thermal properties as PUR, but a chemical different structure.

Expanded polystyrene (EPS) is from the family of polystyrene products, made from cellular plastic.

Extruded polystyrene (XPS) is made from the same material as expanded polystyrene (EPS), but produced through different production processes.

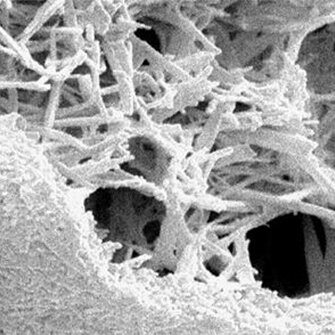

Aerogels are current state-of-art insulation materials made from silica based gel, where the gas replaces liquid components.

Vacuum insulating panels (VIP) are nearly gas-tight enclosures surrounding a rigid core, from which the air has been evacuated and are considered as current state-of-art insulation materials.

Thermal insulating plaster (TIP) is a plaster with incorporated particles of heat insulation with lower thermal conductivity compared with traditionally used plaster.

Calcium silicate is a widely used insulation material for historic buildings. The capillary active structure wicks away the possibility of moisture accumulation.

^

To top